Safety Checks Every Beer Trailer Owner Should Know

Ensuring safety in beer trailers is paramount for successful operations. By conducting regular safety checks, owners can prevent accidents, maintain equipment integrity, and ensure a smooth service experience.

Owning a beer trailer comes with the responsibility of maintaining a safe environment for both staff and patrons. Implementing comprehensive safety checks is essential to prevent mishaps and ensure the longevity of your equipment. By focusing on key areas such as electrical systems, equipment maintenance, and operational protocols, beer trailer owners can get insights into maintaining a secure and efficient setup.

Electrical safety checks for beer trailers

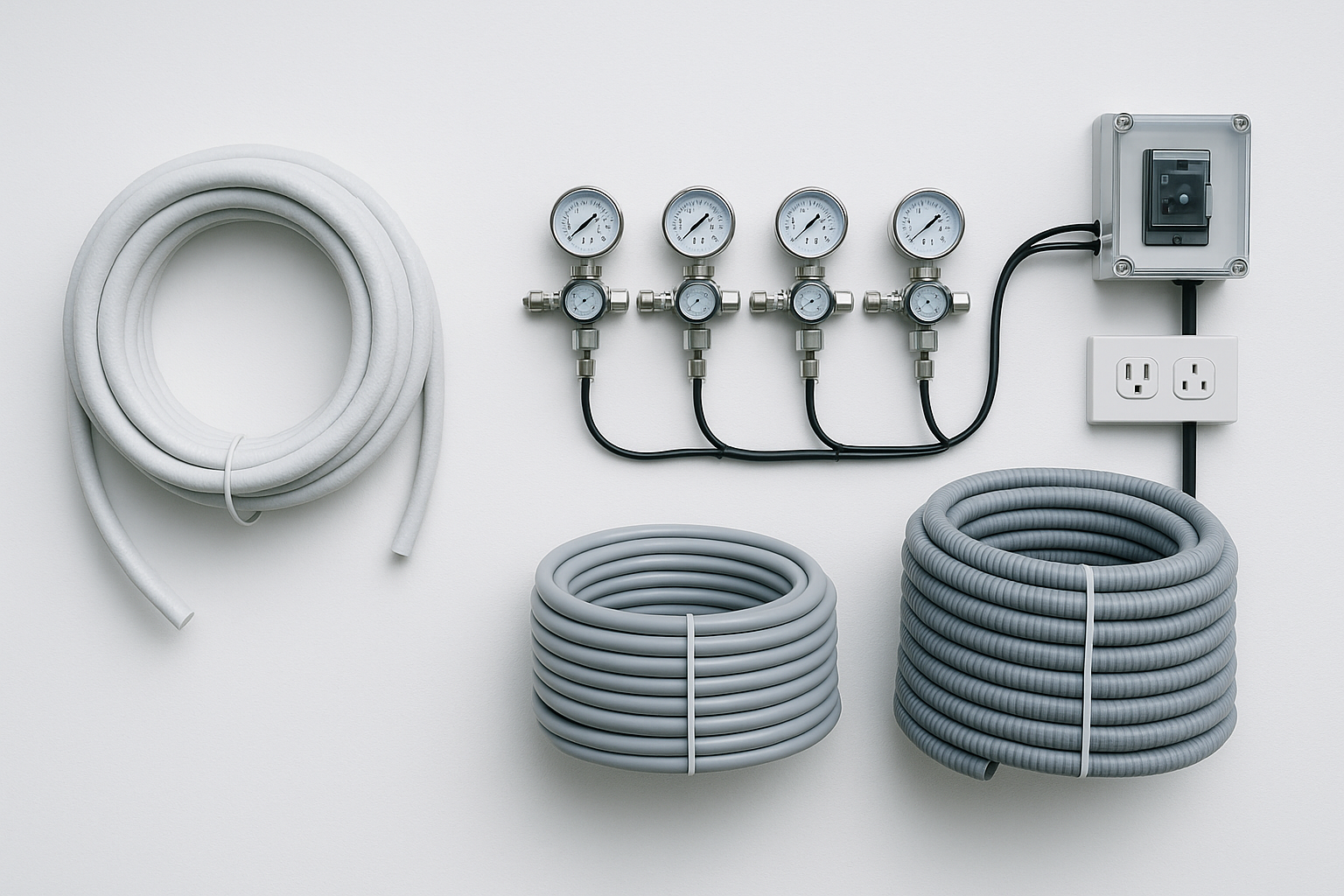

Electrical safety is a critical component of beer trailer operations. Regular inspections of wiring and connections are necessary to prevent electrical hazards. Ensure that all wiring is properly insulated and protected from environmental wear. Using surge protectors can safeguard sensitive equipment from voltage fluctuations, thereby extending their lifespan.

Hiring a certified electrician to conduct routine checks ensures compliance with local electrical codes and reduces the risk of electrical faults. Keeping a detailed log of inspections and repairs helps in tracking maintenance schedules and identifying potential issues before they escalate.

Temperature monitoring systems should also be included in electrical safety protocols. Installing automated temperature alerts and backup power systems helps prevent product loss during power outages. Consider implementing a dual-circuit system where critical cooling equipment operates on a separate circuit from general-purpose outlets, providing an additional layer of protection for your valuable inventory.

Equipment maintenance for optimal performance

Regular maintenance of dispensing equipment is crucial for consistent service quality. Check taps, hoses, and refrigeration units for signs of wear and tear. Cleaning and sanitizing these components regularly prevent contamination and ensure the freshness of your beverages.

Maintaining generators, which are vital for powering your trailer, is equally important. Regularly check oil levels and filters to ensure optimal performance. Keeping a maintenance logbook for generators helps in scheduling timely service and parts replacements, thus avoiding unexpected breakdowns.

Operational protocols and staff training

Establishing clear operational protocols is essential for the safety of both staff and customers. Train staff to recognize potential hazards and respond appropriately in emergencies. Familiarity with emergency shut-off procedures can prevent accidents and minimize damage.

Implementing ground fault circuit interrupters (GFCIs) in key areas, especially where water is present, can protect against electric shocks. Regular audits by safety professionals can provide an unbiased assessment of your trailer’s safety measures, highlighting areas for improvement.

By prioritizing these safety checks, beer trailer owners can ensure a secure and efficient operation, enhancing the overall customer experience and maintaining high safety standards.